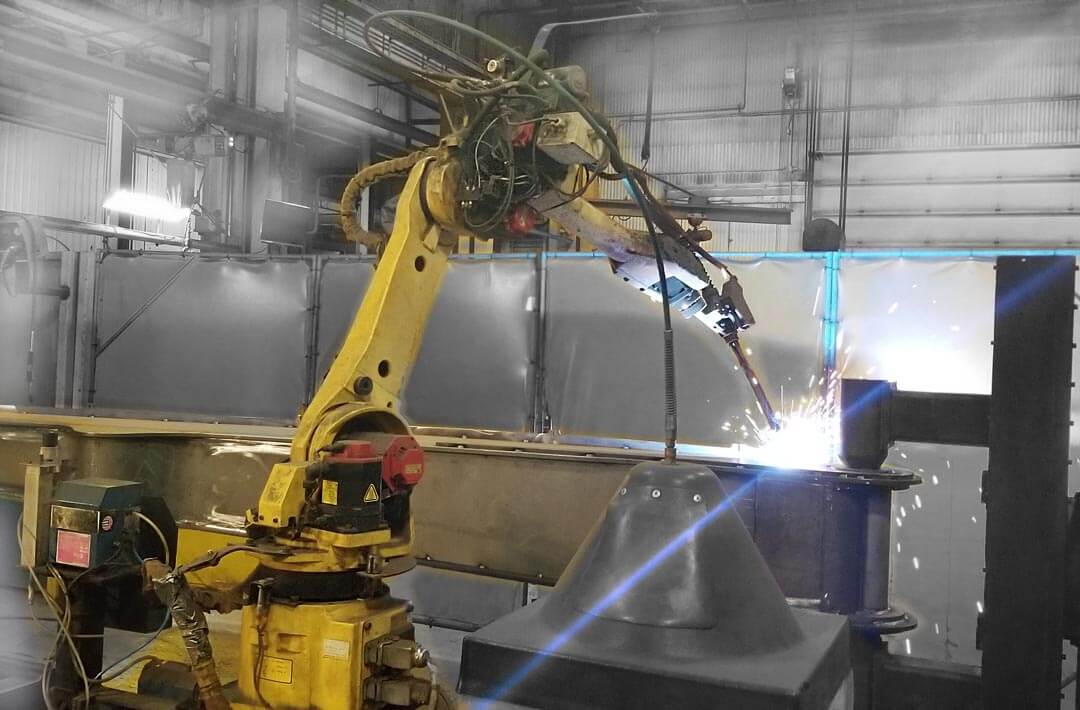

FANUC 2005 Robotic Welder

• Model: ArcMate 120iB/10L

• 6-Axis Arm, Servo Driven

• 2 – Sets Head and Tail Stocks

• 3 – Servo Tracks

• 1 – Robot Base

• 2 – Tail Stocks

• 1 Drop Center

• Software: V7.30P/18/39

• F Number: # F85816

• Touch Sensing

• Seam Tracking

• Safety Package:

• Safety Fencing

• Light Curtain

• Safety Processor

• Locations:

• Prentice, WI

FANUC 2005 Robotic Welder

• Model: ArcMate 120iB/10L

• 6-Axis Arm, Servo Driven

• 1 – 2-Axis Drop Center

• 1 – 1-Axis Drop Center

• Software: Arc Tool V6.40-1M/L

• F Number: # F71425

• Software Options:

• Touch Sensing

• Seam Tracking

• Safety Package:

• Safety Fencing

• Light Curtain

• Safety Processor

• Locations:

• Prentice, WI

AWS Certification

• AWS Certified Welders in D1.1, D1.2, D1.3, D1.6, 1G, 2G, 3G, 4G, 1F, 2F, 3F, 4F, Stainless Steel

• Certified Weld Inspector on Staff

• Locations:

• Granite Falls, MN

• New Ulm, MN

• Prentice, WI

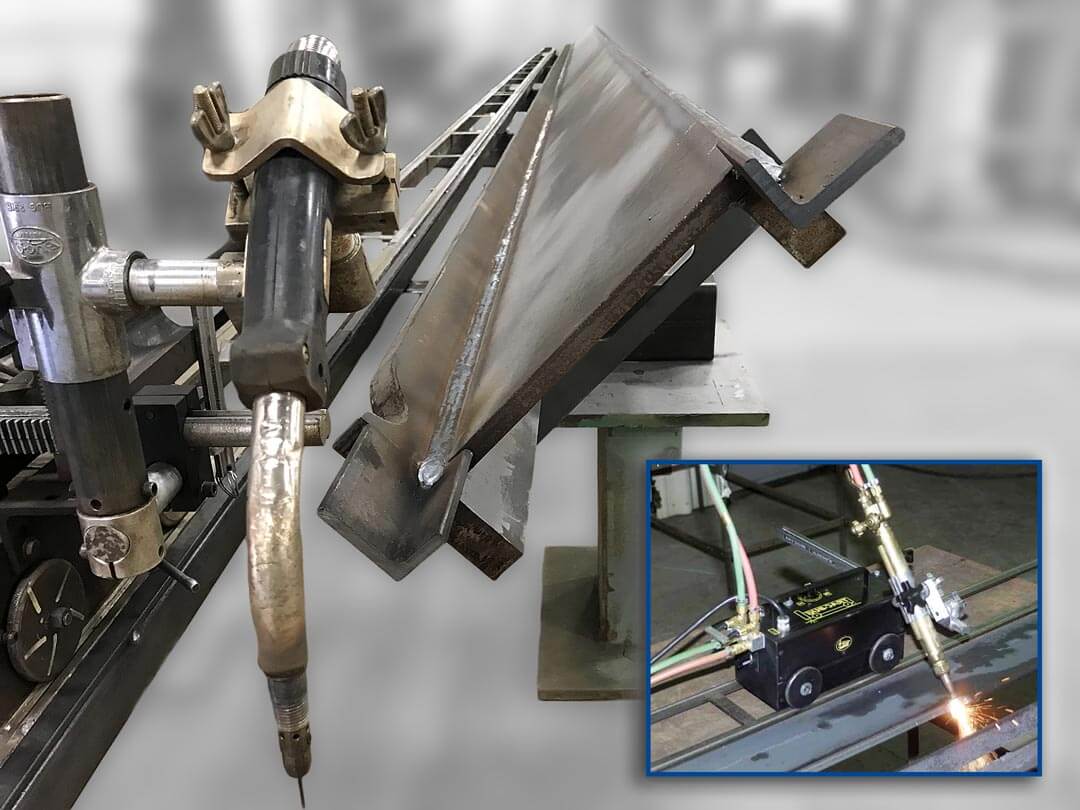

Bug-O Track Welding

• Best Utilized for Low Quantity Runs

• Short Set Up Time

• Consistent Long Welds

• Precise Path on Any Plane or Position

• Consistent Speed Control

• Uniform Heat Input

• Increases Productivity

• Locations:

• Granite Falls, MN

• New Ulm, MN

• Prentice, WI

Sub Arc Welding

• Semi-Automatic (Hand-Held)

• Uniform Heat Input

• Deep Weld Penetration

• Single Pass Welds on Thick Plates with no Spatter of Weld

• Locations:

• Granite Falls, MN

• New Ulm, MN

• Prentice, WI

In-Fixture Production Welding

• Both Customer and SpecSys Engineering Designed Production Fixtures

• Piece Part to Complete Weldment Fixtures

• Consistent and Repetitive Final Weldment

• Drives Out Costs as They Eliminate Weldment Set Up, Tack, and Review

• Locations:

• Granite Falls, MN

• New Ulm, MN

• Prentice, WI

Weld Tables and Jigs

• Tab and Slot Flat Surface

• Stable Work Surface

• Maximizes Welder Productivity

• Keeps Metals Steady to Hold Tolerance During Weld Process

• Holds Multiple Pieces at the Same Time

• Locations:

• Granite Falls, MN

• New Ulm, MN

• Prentice, WI

Positioner

• Manufacturer: Aronson

• Model: HS20GE/TS20GE

• Description: Geared Elevation Headstock/Tailstock Positioner

• Capacity:

• Max Weight Headstock: 20,000lb

• Max Weight Tailstock: 20,000lb

• Table Diameter: 48”

• Table Through Hole: 8”

• Equipped With:

• Pendant Control

• Constant Speed

• 480 Volt 3 Phase

• Locations:

• Granite Falls, MN

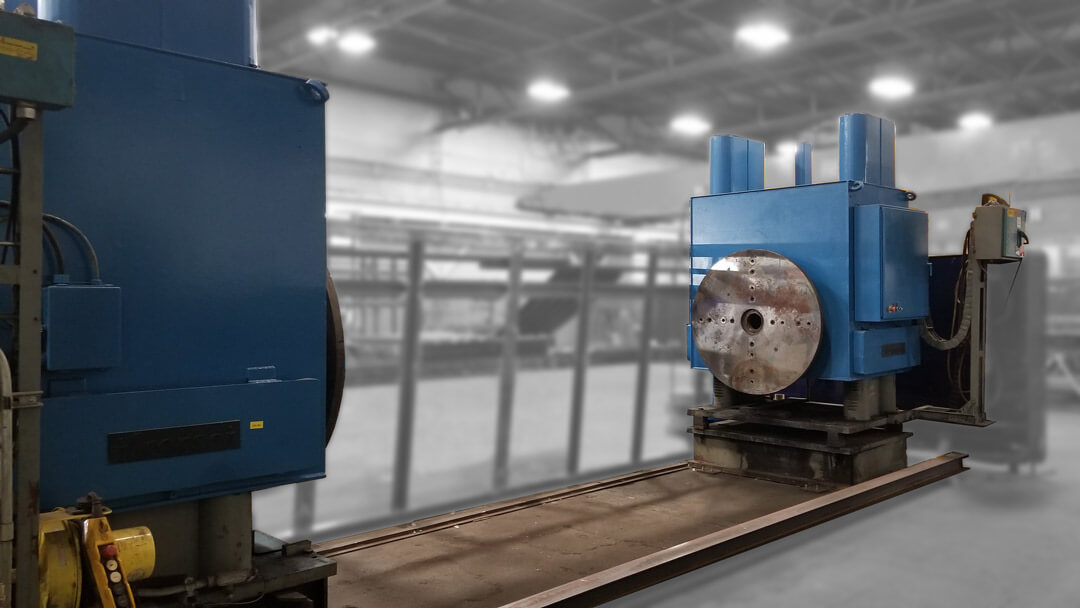

Positioner

• Manufacturer: Koike Aronson

• Model: HTS-40

• Capacity:

• Max Weight Headstock: 20,000lb

• Headstock Model # HS20VF

• Max Weight Tailstock: 20,000lb

• Tailstock Model # TS20

• Table Diameter: 54”

• Table Thru Hole: 8”

• Equipped With:

• Pendant Control

• Constant Speed

• Locations:

• Granite Falls, MN

Small Weld Positioner

• Variety of Load Capacities in Each Facility, 2000lbs to 8000lbs

• Floor Mounted Units

• Allows for Welding in Position

• Locations:

• Granite Falls, MN

• New Ulm, MN

• Prentice, WI

Weld Layout Bed/Table

• Variety of Sizes Located in Each Facility

• Clamps and Tooling Easily Adaptable for Welding

• Solid Work Surface for Welder

• Locations:

• Granite Falls, MN

• New Ulm, MN

• Prentice, WI